- Disruptive Technologies, a Norwegian company, has developed a sensor that can be stuck almost anywhere and sends encrypted measurement data.

- Versatile fields of application for secure, cost-optimized and sustainable operational sequences

- Zollner Elektronik AG created a novel production line in-house because the designed space is extremely compressed, and the sensor housing needs to be absolutely robust.

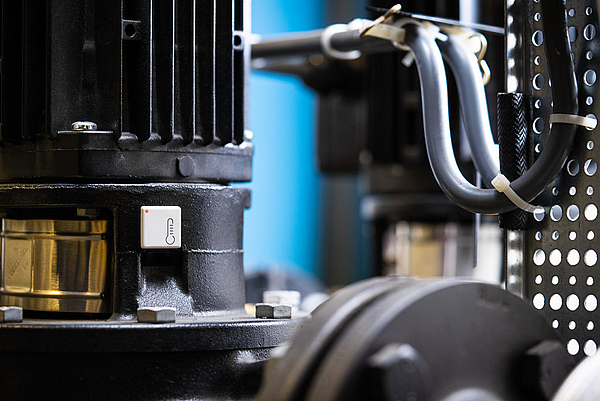

Zollner Elektronik AG manufactures a sensor for Disruptive Technologies with which the Norwegian startup wants to contribute to more effective networking in the Internet of Things (IoT). To do this the EMS company from Zandt needed to make the prototype reproducible. Disruptive Technologies developed a tiny sensor that can be mounted with adhesive to just about anything and is the core piece of a solution to make the collection and evaluation of data easier. This innovation entered the market in 2019.

For the conversion of the prototype into a marketable product that can be produced in large-scale serial production, Zollner Elektronik AG worked for two years on a completely custom-designed production line and constantly improved on it. We adapted existing and known technologies to the new requirements and applied new and novel technologies as well. The line is capable of manufacturing eleven million sensors a year and can be expanded to meet the 35 million pieces they are striving toward.

Pippa Boothman, Vice President Marketing & Communications at Disruptive Technologies, gave praise: “Zollner Elektronik AG is a consummate partner for Disruptive Technologies. With its uncompromising attention to producibility, reproducibility and quality it was able to convert our concepts into stable large-scale serial production. Its networks, know-how and knowledge of reliable suppliers and subcontractors made it possible to establish automated processes for the assembly and efficient handling of our miniature devices.”

Sensor solution with potential to transform the entire living environment

IoT-capable devices, the founder of Disruptive Technologies thought, were too expensive and hard to handle for comprehensive distribution. In 2013 he started to change that when he developed a sensor 19 x 19 x 2.5 mm small, just about as big as a keyboard key and as thick as a coin. The sensor can also be attached in difficult to reach places to measure, for example, the temperature and relative humidity. Its data is transmitted to a Cloud Connector, which is also manufactured by Zollner. This is a link station, which securely forwards encrypted data into the cloud. There they remain permanently available in real time and serve as a basis for optimal resource management.

The common applications for this sensor solution are, among others, cold storage monitoring to prevent food waste, monitoring transformer stations to increase supply security or monitoring temperatures in water pipes, which prevents the development of legionella bacteria, which is hazardous to health. With the ability to remotely monitor buildings, this solution also allows for desk occupancy, smart cleaning and energy efficiency and sustainable operations. In factories and warehouses the sensor solution from Disruptive Technologies can increase productivity, prevent downtimes and lower maintenance costs.

Partially automated production line for large-scale serial production

Many challenges needed to be overcome by Zollner Elektronik AG in the production of these mini sensors. The available volume for the electronics is extremely small. A tiny battery is attached to a very thin circuit board. Additionally, the whole assembly needed to be completely encapsulated to fulfill the IP68 standard and others. The goal was to make the product absolutely waterproof and dust-proof and cover the industrial temperature range of -40 to +85 degrees Celsius.

The manufacturing line employs techniques like wire bonding, laser cutting, vacuum forming, resin casting and massive robotization. Combining these techniques in innovative ways has resulted in a very cost efficient and high quality manufacturing process.

Bernhard Kiefl, head of the responsible Business Division at Zollner Elektronik AG says: “It was a tremendous task to convert the requirements of the customer into a production system for high-volume manufacturing. We integrated numerous new technologies into the production line so we could achieve the desired result. A lot of existing know-how flowed into the system, while at the same time we were gaining even more, new knowledge.”