We are optimally equipped for the production of your electronics – we offer flexible and reliable individual services just as you need them.

We cover the entire spectrum of EMS services for you in the area of electronics – from PCBA production all the way to complete devices and systems. We stand at your side throughout the complete value-added chain. Completely regardless of the location at which we produce for you, you invariably receive the highest level of quality due to standardized machining facilities and equipment, uniform workflows and monitored processes. This applies to niche technologies or special processes. Production in a controlled environment or cleanroom, as well as under customer-specific conditions, is also possible due to the modern building infrastructure.

A one-of-a-kind MES system allows for gapless traceability that meets requirements from receiving to delivery or after many years in the field for refurbishment or repair. This standardized system across all locations is continuously being further developed by in-house experts and supported 24/7.

Fully automated storage systems in production, self-driving transport systems, cobots and the application of AI solutions ensure stable operation and make it possible for us to deploy our employees to the places where they are most valuable.

Qualified employees are the basis for mastered processes. Zollner has its own training center in which certified IPC trainers impart both theoretical knowledge during multi-week training courses but also individual skills for manual soldering, repair soldering and working with hot gas stations. Practical training on production systems is executed in our own technical school according to industry standards. Zollner, together with partners, developed a modular training concept (www.avle-training.de).

Even in the early stages of the product development process, we can support you with design analysis to prepare a production-ready, robust product for industrial production. Alongside conventional analyses, DfM (Design for Manufacturing), DfT (Design for Testability), DfA (Design for Assembly), DfR (Design for Repair) and DtC (Design to Cost), we can also support you with DfS (Design for Sustainability) and DfAA (Design for Automated Assembly). Simulations are possible, all the way to 3D tours through future production lines.

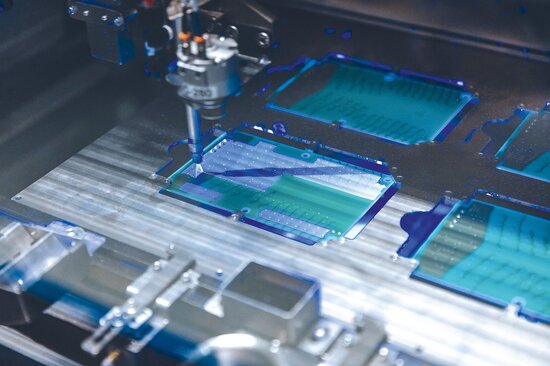

In the area of PCBA production, we produce in accordance with recognized industry standards like J-STD-001 and IPC-A-610 but also according to special requirements in the Automotive Technology, Healthcare & Life Sciences, Test & Measurement, Aerospace and Defense sectors.

For their products we have a highly modern set of machines as well as monitored manual process steps precisely there where they are needed. Standard processes in the SMT and THT area are also familiar to us, like laser soldering, thick and thin wire bonding, laser welding, ACF bonding or underfill.

Comprehensive test options in the optical area (SPI, AOI, X-ray) as well as in electrical testing (ICT, functional test, boundary scan, run-in, burn-in) are the basis for reliable products with warranted characteristics. Our own in-house tester and fixture design and construction department with expertise in high voltage, high current and high frequency applications guarantees expert knowledge of common testing techniques.

If your product is operated in a rough environment, we have diverse processes for the protection of your electronics. Next to preliminary cleaning processes, this also includes comprehensive protection for your assembly like conformal coating, casting or special technologies like nanocoating.

From low piece counts to several hundred thousand per year as well as from product introduction through serial production and on to product phaseout, we offer individually scalable solutions. Our own special machine design and construction department with many years of process experience supports us in implementation. This includes both process technology and programming of the control systems.

The implemented spectrum to date stretches from small modules that are produced on fully automated lines up to systems that are several cubic meters in size that are produced semi-automatically or manually.

Long standing experience in 3D printing offers the possibility of creating single parts during the sample phase quickly and without great effort. The following processes are being used currently at Zollner: DLP (Digital Light Processing), SLS (Selective Laser Sintering), FDM (Fused Deposition Modeling) and SLA (Stereolithography). Alongside the machining facilities and equipment, the material utilized is enormously important. Here, in cooperation with suppliers, materials with special characteristics are developed (e.g.: ESD compliant and simultaneously resistant to high temperatures) in order to expand the area of application of these technologies.