We manufacture at our numerous production sites in both high and low quantities according to requirements and also offer individual additional services - always cost-effectively, flexibly and to a high quality.

Next-generation production - whether individual components, modules or devices and systems in low volume with high value-added content or as highly automated high volume production, you’ve found the right partner. Low-volume-high-mix or high-volume-low-mix - our highly flexible production system enables us to realize both economically. Put your trust in decades of experience and a wide range of technologies to transform your ideas into reality. In order to perfectly meet your individual needs and ensure your product demands are met, we realize customized processes that are specifically geared to the characteristics and cost aspects of the product. With this in mind, we repeatedly plan, create and optimize individual workstations and complete production lines. With our modern special machine construction, we also draw on extensive experience in process design. The basis for this is a digital image of the product and its production process (digital twin), which enables us to plan the entire production without having the physical product in our hands – Digital Factory.

We offer a wide range of technologies as well as comprehensive expertise:

As a driver of innovation and technology, we are guided by environmental as well as economic standards and work according to a local-for-local strategy. We choose the best individual solution for our customers based on their specific requirements. We offer the same high level of quality and flexibility at all sites to ensure consistent processes across the board. All production takes place on cutting-edge machines and equipment as well as with the latest technology, to ensure both sustainable and cost-effective production at the same time. Our products are produced in a resource-conserving manner in order to make a significant contribution to sustainability in manufacturing. Even after manufacturing of the product is complete, we ensure sustainable waste management. This includes, for example, careful waste separation including sorting and recycling of various materials, shredding of old assemblies and compressing packaging materials. What’s more, we pay particular attention to our swarf handling by efficiently briquetting aluminum swarf generated in production to reduce volume and residual moisture. By briquetting the aluminum remnants, we not only increase the value of the material, but at the same time save emissions and can recycle the aluminum briquettes more sustainably.

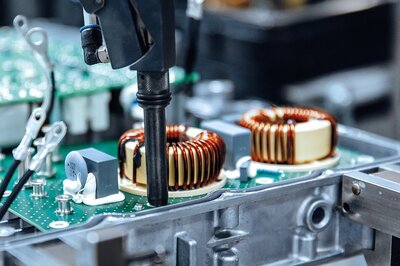

In the field of electronics, we are able process the entire range of components for you with high quality and the necessary efficiency. The state-of-the-art SIPLACE generations we use in the SMT sector are the best proof yet. We test your products with the most modern test equipment. This includes AOI and X-ray inspection as well as flying probe, boundary scan, ICT and a functional test.

In our mechanical production we use various punching-laser combinations, manual and highly automated bending technologies as well as various welding processes (TIG, MAG or laser welding) in sheet metal processing and the most modern painting and laser marking systems. Our range of services includes CNC turning (short and long turning) and CNC milling (3 and 5-axes) in the field of machining and galvanic surface finishing. Our aim is always the same: We want to produce products for you economically, flexibly and with the highest quality.

For our winding processes, we use all common winding technologies as standard, such as multi-axis systems or standard table winding machines. We realize large series using fully automatic coil processing systems, in which, in addition to multi-axis winding u.a. Processes such as laser welding, gluing, laser marking or automated packaging are integrated. If the common dip soldering method is not sufficient for contacting the wires, resistance, ultrasonic or laser welding methods can also be used. In addition, our range of services includes the casting of epoxy, polyurethane or silicone resins (vacuum or non-vacuum) or the vacuum impregnation of coils in resins. Our goal is to be able to offer manufacturing processes at the highest level of quality on a sustainable basis.

At our sites in Germany and China, we have created clean rooms (ISO 5, 7 & 9) for our customers.