Quality made to measure – in the field of Sheet Metal Processing we offer modern and highly automated manufacturing options.

Integrated automatic storage system for large format plates in Szügy, Hungary

Storage places: 908

Sheet large format: 1525 x 3050 mm

Total storage weight: 2724 t

Material: Mild steel, stainless steel, aluminum, copper

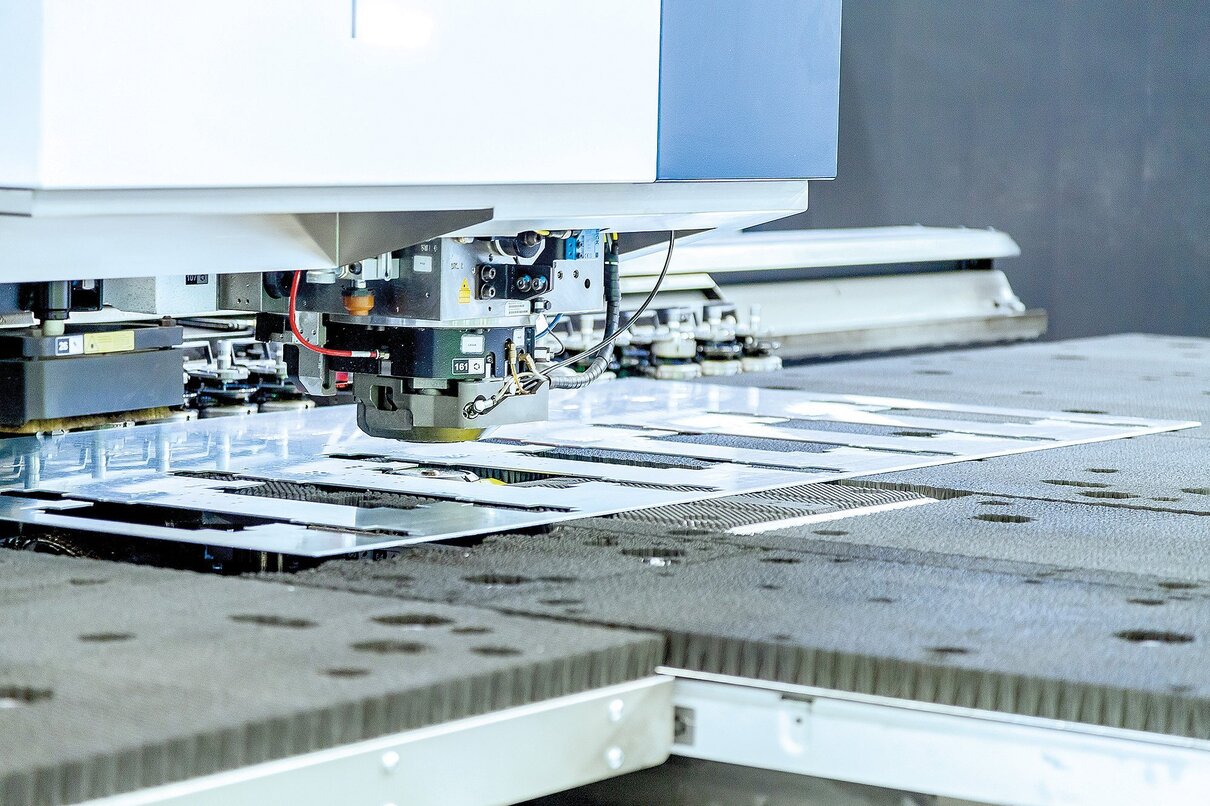

Punching or as punch-laser combined technology

Max. sheet thickness: 6.4 mm

Max. workpiece weight: 150 kg

Max. punching force: 180 Nm

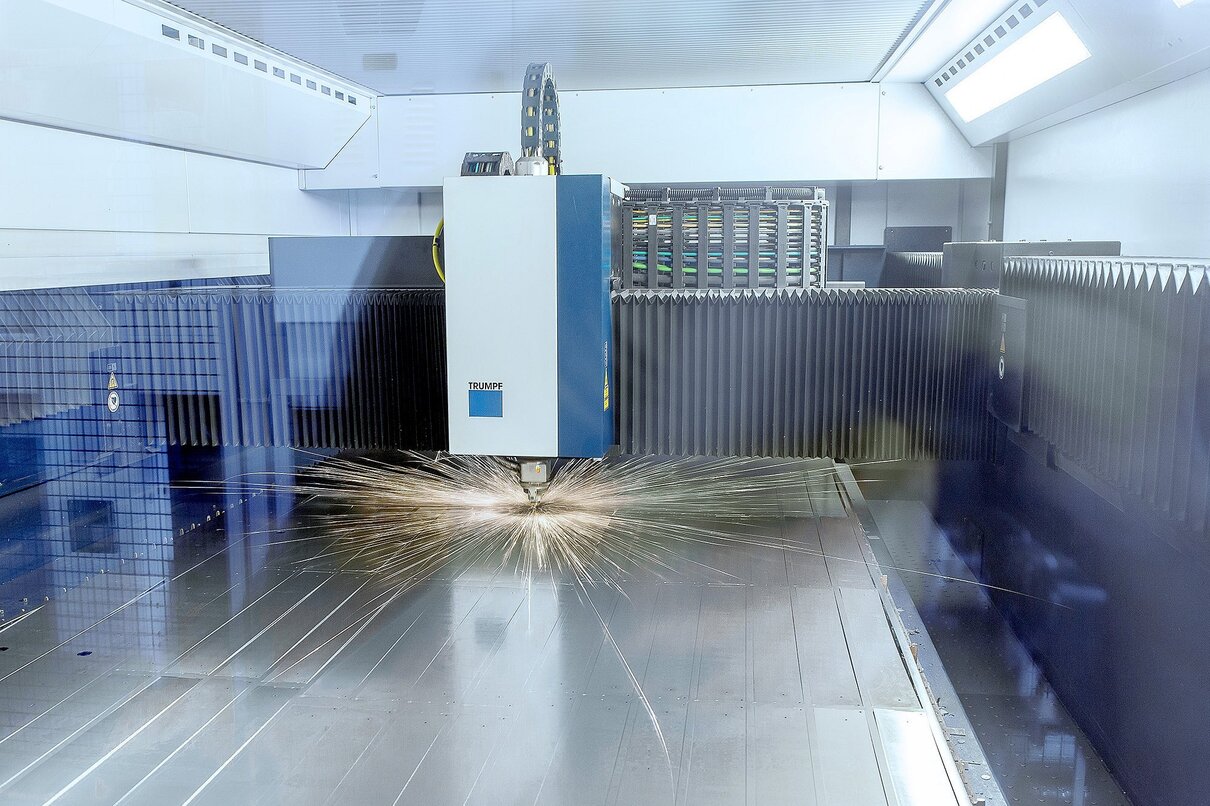

CO2 or solid-state laser

Max. laser power: 6000 W

Max. sheet thickness mild steel / stainless steel / aluminum: 25 mm

Max. sheet thickness copper / brass: 10 mm

Bending machine

Pressing force: 360 kN

Bevel length: 1020 mm

Loading station

Number of axes: 4

Repeatability: ±0.01 mm

Bending robot

Number of axes: 6

Repeatability: ±0.035 mm

Bending center

Max. workpiece size: 2795 x 1524 mm

Max. bending length: 2500 mm

Max. bending height: 165 mm

Max. sheet thickness: 2.10 mm at 410 N/mm²

Welding robot, high-accuracy robot and working area

Welding robot

Max. laser power: 4000 W

Beam quality: 8 mm * mrad

High-accuracy robot

Number of axes: 6

Repeatability: ±0.05 mm

Working area

Max. 1600 x 800 x 700 mm

Max. 250 kg

Installation of assemblies, devices, and systems